Dual-Axis Nanopositioners

- Stock: 4 to 6 weeks

- Click here to: Contact us

- Model: nPoint Dual-Axis Nanopositioners

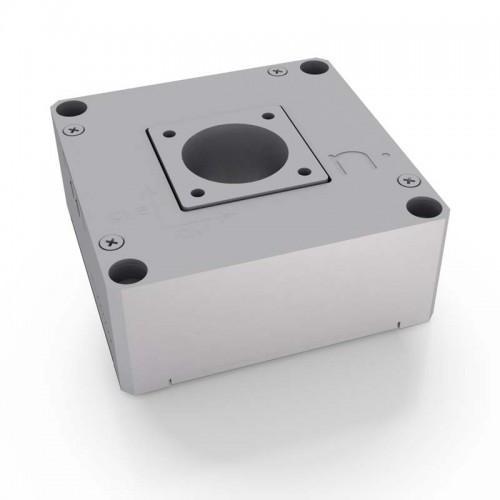

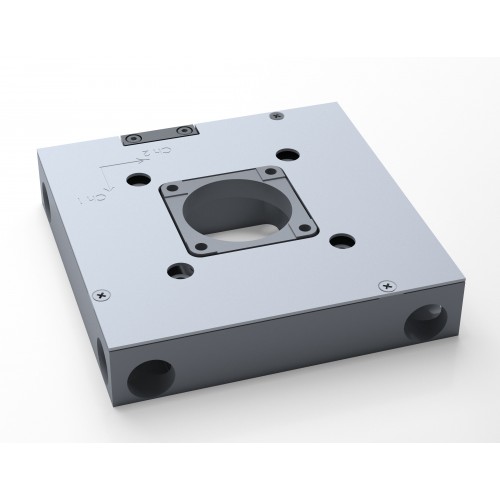

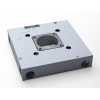

XY nanopositioning piezo stages

nPoint Dual Axis Nanopostioners

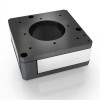

nPoint's specialised piezo-driven flexure-guided nanopositioners are designed for many motion critical operations, such as scanning and position control. Typical precision applications include nanolithography, atomic force microscopy (AFM), biophysics, and optical focusing.

The NPXY range of piezo stages offer up 1000 µm of motion depending on model, and their unique flexure-guided designs ensure high resonant frequencies while minimising orthogonality and cross-talk errors.

The nPoint 400 series DSP controllers provide flexibility in programming and allow easy optimisation of piezo system response times for a variety of applications.

Standard stage materials are listed. Other materials, including invar, super invar, stainless steel, titanium, and aluminum, are available for some stages. UHV configurations are also available in most products. Please enquire if interested in these options.

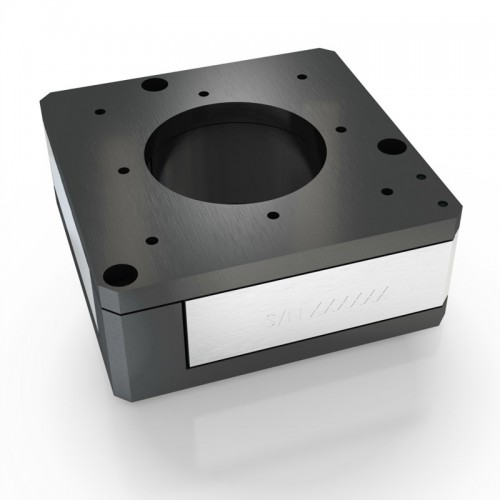

| XY Models | NPXY 40-467 |

NPXY 50-286 |

NPXY 60-258 |

NPXY 90-498 |

| < 99 µm of motion |  |

|

|

|

| Key features: | For optics Small & light |

Compact High resonance |

Non-magnetic UHV compatible |

Fast response |

| Footprint (mm) | 25 x 25 | 60 x 60 | 70 dia. | 84 x 84 |

| Height (mm) | 12.5 | 25 | 30 | 18 |

| Aperture (mm) | None | 20 dia. | 30 dia. | 27 dia. |

| Body Material | Stainless Steel | Aluminium | Stainless Steel | |

| Maximum Load (kg) | 0.1 | 1 | ||

| Stage Mass (kg) | 0.25 | 0.38 | 0.52 | |

| Max Push/Pull Force (N) | 10/1.5 | 100/20 | 100/70 | |

| Closed-loop Travel (µm) | 40 | 50 | 60 | 90 |

| Open-loop Travel* (µm) | 50 | 70 | 120 | |

| Position Noise (nm) | 2 | 0.2 | 0.4 | 0.5 |

| Stiffness (N/µm) | 1.4 | 8 | 2.3 | |

| Resonant Freq. (kHz) X-axis Y-axis |

0.735 0.84 |

1.4 1.4 |

0.75 0.75 |

0.9 0.9 |

| Linearity Deviation (%) | 0.1 | 0.01 | 0.03 | 0.01 |

| Settling Time (ms) | 4.5 | 4 | 5 | 4 |

| Capacitance (µF) | 2.8 | 4.3 | ||

| Integrated Sensor | Strain Gauge | Capacitive | Capacitive | |

| Controller | LC.402 | |||

| Notes | * Open-loop Travel operating at -30 to 150 V | |||

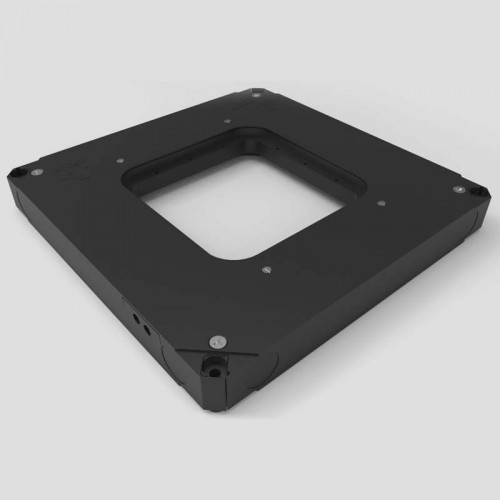

| XY Models | NPXY 100-100 |

NPXY 100-126 |

NPXY 200-401 |

NPXY 200-101 |

| < 199 µm of motion |  |

|

|

|

| Key features: | Ultra-precise For metrology |

Low profile Large aperture |

Low profile Large aperture |

Ultra-precise For metrology |

| Footprint (mm) | 100 x 100 | 140 x 140 | 140 x 140 | 100 x 100 |

| Height (mm) | 23 | 17 | 17 | 23 |

| Aperture (mm) | 40 dia. | 68 x 68 | 68 x 68 | 40 dia. |

| Body Material | Aluminium | |||

| Maximum Load (kg) | 1 | 5 | 5 | 1 |

| Stage Mass (kg) | 0.46 | 0.55 | 0.57 | 0.46 |

| Max Push/Pull Force (N) | 100/20 | |||

| Closed-loop Travel (µm) | 100 | 100 | 200 | 200 |

| Open-loop Travel* (µm) | 160 | 160 | 250 | 290 |

| Position Noise (nm) | 0.3 | 0.3 | 0.7 | 0.5 |

| Stiffness (N/µm) | 1.2 | 3.3 | 2.1 | 0.5 |

| Resonant Freq. (kHz) | 0.7 | 0.85 | 0.7 | 0.4 |

| Linearity Deviation (%) | 0.01 | |||

| Settling Time (ms) | 6 | 5 | 8 | 15 |

| Capacitance (µF) | 2.4 | 4.8 | 7.5 | 3.1 |

| Integrated Sensor | Capacitive | |||

| Controller | LC.402 | |||

| Notes | * Open-loop Travel operating at -30 to 150 V | |||

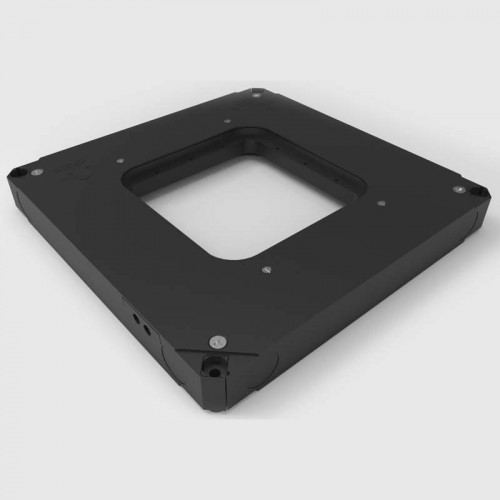

| XY Models | NPXY 250-40 |

NPXY 300-291 |

|

| 200+ µm of motion |  |

|

|

| Key features: | For microscopy Low cost |

Fast Large aperture |

|

| Footprint (mm) | 75 x 75 | 179 x 179 | |

| Height (mm) | 30 | 23 | |

| Aperture (mm) | 40 dia. | 85 x 95 | |

| Body Material | Mixed† | Aluminium | |

| Maximum Load (kg) | 1 | 5 | |

| Stage Mass (kg) | 0.35 | 1.56 | |

| Max Push/Pull Force (N) | 100/10 | 100/20 | |

| Closed-loop Travel (µm) | 250 | 300 | |

| Open-loop Travel* (µm) | 340 | 360 | |

| Position Noise (nm) | 4 | 1 | |

| Stiffness (N/µm) | 0.5 | 0.7 | |

| Resonant Freq. (kHz) X-axis Y-axis |

0.30 0.23 |

0.24 0.24 |

|

| Linearity Deviation (%) | 0.05 | 0.01 | |

| Settling Time (ms) X-axis Y-axis |

10 15 |

20 20 |

|

| Capacitance (µF) | 3.0 | 8.2 | |

| Integrated Sensor | Strain Gauge | Capacitive | |

| Controller | LC.402 | ||

| Notes | * Open-loop Travel operating at -30 to 150 V † Mixed material is aluminium and stainless steel |

||

| File Name | Size | Link |

|---|---|---|

|

|

207.42KiB | Download |

A number of papers have been published by scientists around the globe who have used nPoint stages within their research. Here are some examples:

- Continuous scanning mode for ptychography

- Effect of proteoglycans at interfaces as related to location, architecture, and mechanical cues

- nDSE Based Overlay Alignment: Enabling Technology for Nano Metrology and Fabrication

- OMNY—A tOMography Nano crYo stage

- A Discrete-Time Single-Parameter Combined Feedforward/Feedback Adaptive-Delay Algorithm With Applications to Piezo-Based Raster Tracking